How to ensure the safety of energy storage? Intelligent BMS casting protective shield

In recent years, driven by the strong trend of the new energy industry, many countries and regions have elevated energy storage to a strategic level of national energy security. However, on the back of the booming development of the energy storage industry, frequent safety accidents in energy storage power stations have become a hidden pain that cannot be ignored in the industry.

On June 24th, a fire broke out at Aricell's lithium battery factory in South Korea, resulting in the unfortunate death of 23 workers. According to experts' speculation, the accident is likely due to the thermal runaway and explosion of a single battery, which triggered a chain reaction of surrounding batteries and ultimately led to a tragedy. Prior to this, on June 7th, a fire broke out at the Suncycle Engineering Testing Center in Thuringia, Germany, involving a containerized battery energy storage system. The local fire department took about 4 hours to extinguish the fire, resulting in an economic loss of approximately 700000 euros. The cause of the accident is currently unclear, and it is preliminarily suspected to be related to technical defects.

According to incomplete statistics, there have been over 70 energy storage accidents worldwide since 2023, most of which are caused by internal cell failures leading to battery and module failures or external auxiliary system failures causing thermal runaway of energy storage systems. The key to improving energy storage safety lies in the upgrading of system prediction and warning capabilities and battery thermal management technologies.

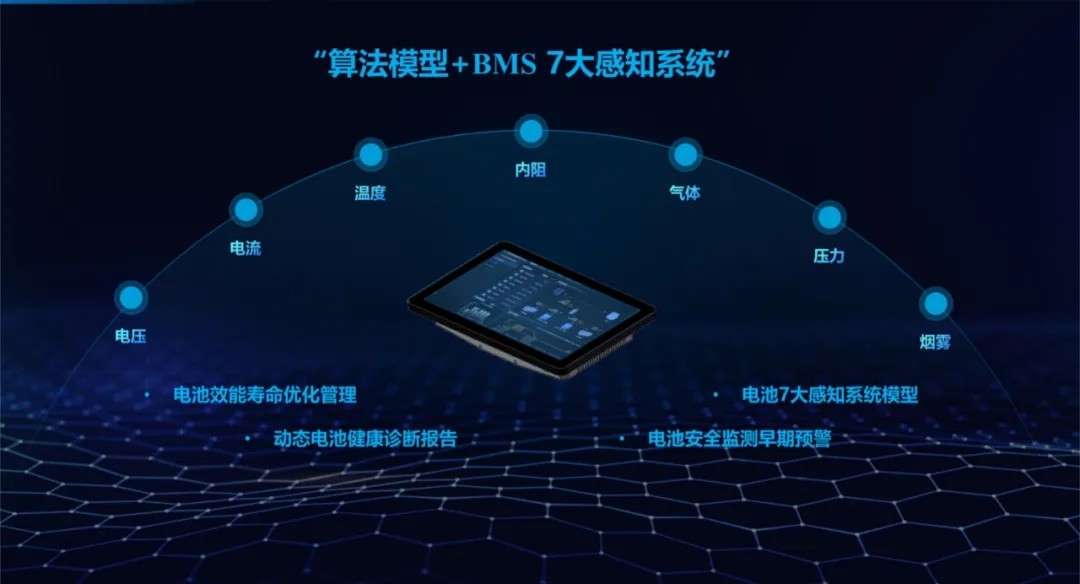

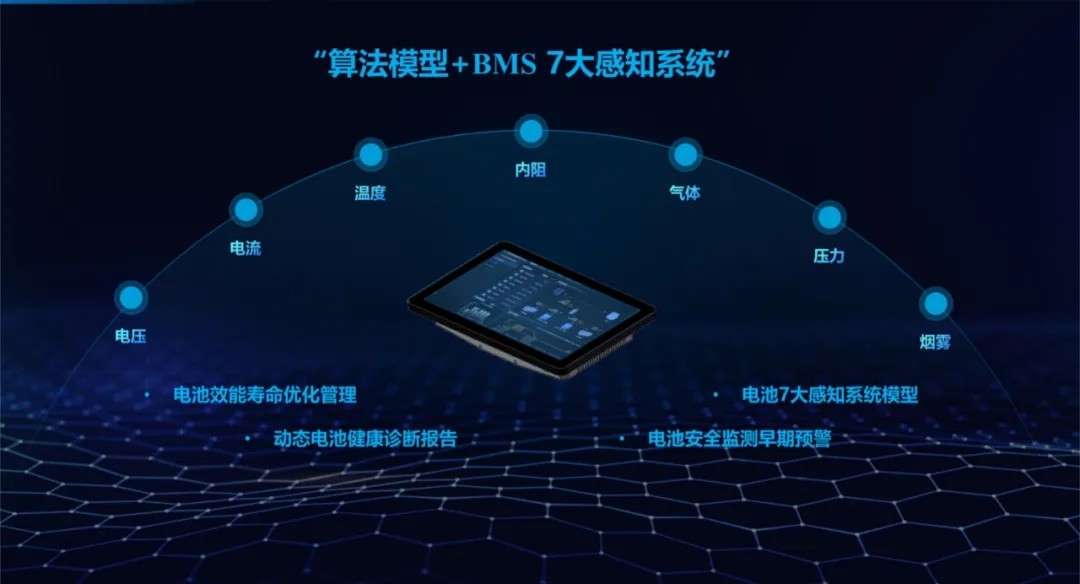

The future of energy storage lies in safety, and only by holding onto the safety bottom line can the energy storage industry achieve healthy and sustainable development. As the safety hub of energy storage systems, the importance of BMS is becoming increasingly prominent. The BMS system is the core equipment for visualizing and controlling the status of energy storage batteries. It collects key parameters such as voltage, current, and temperature of the battery pack to determine the health, energy, and safety status of the battery, thereby ensuring the safe and reliable operation of the energy storage system. It is worth mentioning that the accuracy and reliability of the data obtained by BMS directly determine the safety and efficiency of the overall operation of the energy storage system.

At present, the energy storage industry is showing a diversified development trend, with increasingly diverse demands and scenarios. The system needs to handle more complex data sources and huge data management requirements. The application of digital technologies such as the Internet of Things, big data, and AI provides solid technical support for improving the data processing capabilities of energy storage systems.